Ceramic engineering

Ceramic engineering is the technology that involves the design and manufacture of ceramic products. Ceramics are inorganic, nonmetallic materials that have been hardened by baking at high temperatures. Highly regarded for being resistant to heat, these materials can be used for many demanding tasks that other materials, such as metals and polymers, cannot.

Until about the mid-twentieth century, the most important ceramics were the traditional clays, which were made into pottery, dinnerware, bricks, tiles, and decorative items. Since then, new materials called advanced ceramics have been prepared and are being used for a wide range of applications, including components used by the aerospace, automotive, defense, environmental, fiber-optic, and medical technologies. Ceramic parts are also used in cellular phones and personal computers. In addition, ceramic engineering is useful in such areas as petroleum refining, food processing, packaging, and mining.

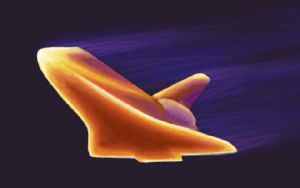

Traditional ceramic raw materials include clay minerals such as kaolinite. Modern ceramic materials include silicon carbide and tungsten carbide, both of which are highly resistant to abrasion and are used in applications such as the wear plates of crushing equipment in mining operations. Each of NASA's Space Shuttles has a coating of ceramic tiles that protect it from the searing heat (up to 2,300 °F) produced during reentry into Earth's atmosphere. Thus, ceramic engineering is an important contributor to the modern technological revolution.

History

Abraham Darby first used coke in 1709, in Shropshire, England, to improve the yield of a smelting process. Coke is now widely used to produce carbide ceramics. Potter Josiah Wedgwood opened the first modern ceramics factory in Stoke-on-Trent, England, in 1759. Austrian chemist Karl Bayer, working for the textile industry in Russia, developed a process to separate alumina from bauxite ore in 1888. The Bayer process is still used to purify alumina for the ceramic and aluminum industries. Brothers Pierre and Jacques Curie discovered piezoelectricity in Rochelle salt circa 1880. Piezoelectricity is one of the key properties of electroceramics.

In 1893, E.G. Acheson heated a mixture of coke and clay, and invented carborundum, or synthetic silicon carbide (SiC). Henri Moisson also synthesized SiC and tungsten carbide in his electric arc furnace in Paris about the same time as Acheson. Karl Schröter used liquid-phase sintering to bond or "cement" Moissan’s tungsten carbide particles with cobalt in 1923, in Germany. Cemented (metal-bonded) carbide edges greatly increase the durability of hardened steel cutting tools.

Walther Nernst developed cubic-stabilized zirconia (CSZ) in the 1920s in Berlin. CSZ is used as an oxygen sensor in exhaust systems. W.D. Kingery and others in the 1950s developed partially stabilized zirconia (PSZ), greatly increasing its toughness. PSZ is used to make cutlery and other tools. Lead zirconate titanate (PZT) was developed at the United States National Bureau of Standards in 1954. PZT is used as an ultrasonic transducer, as its piezoelectric properties greatly exceed those of Rochelle salt.[1]

The first ceramic engineering course and department in the United States were established by Edward Orton, Jr., a professor of geology and mining engineering, at the Ohio State University in 1894. Orton and eight other professionals founded the American Ceramic Society (ACerS) at the 1898 National Brick Manufacturers' Association convention in Pittsburgh. Orton was the first ACerS General Secretary, and his office at OSU served as the society headquarters in the beginning. Charles F. Binns established the New York State School of Clay-Working and Ceramics, now Alfred University, in 1900. Binns was the third ACerS president, and Orton the 32nd.[2] The Ceramic Society of Japan was founded in 1891 in Tokyo. Deutschen Keramischen Gesellschaft, the ceramic society of Germany, was founded in Berlin in 1919.

The military requirements of World War II (1939-1945) encouraged developments that created a need for high-performance materials and helped speed the development of ceramic science and engineering. Throughout the 1960s and 1970s, new types of ceramics were developed in response to advances in atomic energy, electronics, communications, and space travel. The discovery of ceramic superconductors, in 1986, has spurred intense research to develop superconducting ceramic parts for electronic devices, electric motors, and transportation equipment.

Preceding the spark of the ceramic industry in the late nineteenth century, there was the study of materials closely associated with chemistry. Since ceramics have a crystalline structure, knowledge of crystal formation and the strengths involved was important in the development of ceramics as a stand-alone scientific field.

Properties of ceramics

A ceramic material may be generally defined as any inorganic crystalline oxide material. It is solid and inert. Ceramic materials are brittle, hard, strong in compression, weak in shearing and tension. They withstand chemical erosion that occur in an acidic or caustic environment. In many cases withstanding erosion from the acid and bases applied to it. Ceramics generally can withstand very high temperatures such as temperatures that range from 1,000°C to 1,600°C (1,800°F to 3,000°F). Exceptions include inorganic materials that do not have oxygen such silicon carbide. Glass by definition is not a ceramic because it is an amorphous solid (non-crystalline). However, glass involves several steps of the ceramic process and its mechanical properties behave similarly to ceramic materials.

The ceramic process

The ceramic process generally follows this flow.

Milling → Batching → Mixing → Forming → Drying → Firing → Assembly

Milling is the process by which materials are reduced from a larger size to a smaller size. Milling may involve breaking up cemented material, thus the individual particle retain their shape or pulverization which involves grinding the particles themselves to a smaller size. Pulverization is actually fracturing the grains and breaking them down.

Generally, milling is done through mechanical means. The means include attrition which is particle to particle collision that results in agglomerate break up or particle shearing. Compression which is applying compressive forces that result in break up or fracturing. Another means is impact which involves a milling media—or the particles themselves—that cause break up or fracturing.

Examples of equipment that achieve attrition milling is a planetary mill or an wet attrition mill, also called wet scrubber. A wet scrubber is a machine that has paddles in water turning in opposite direction causing two vortexes turning into each other. The material in the vortex collide and break up.

Equipment that achieve compression milling include a jaw crusher, roller crusher, and cone crushers.

Finally, impact mills may include a ball mill with media that tumble and fracture material. Shaft impactors cause particle to particle attrition and compression which achieve size reduction.

Batching is the process of weighing the oxides according to recipes, and preparing them for mixing and drying.

Mixing occurs after batching and involve a variety of equipment such as dry mixing ribbon mixers (a type of cement mixer), Mueller mixers, and pug mills. Wet mixing generally involve the same equipment.

Forming is making the mixed material into shapes, ranging from toilet bowls to spark plug insulators. Forming can involve: Extrusion, such as extruding "slugs" to make bricks, Pressing to make shaped parts, or slip casting, as in making toilet bowls, wash basins and ornamentals like ceramic statues. Forming produces a "green" part, ready for drying. Green parts are soft, pliable, and over time will lose shape. Handling the green product product will change its shape. For example, a green brick can be "squeezed," and after squeezing it will stay that way.

Drying is removing the water or binder from the formed material. Spray drying is widely used to prepare powder for pressing operations. Other dryers are tunnel dryers and periodic dryers. Controlled heat is applied in this two-stage process. First, heat removes water. This step needs careful control, as rapid heating causes cracks and surface defects. The dried part is smaller than the green part, and is brittle, necessitating careful handling, since a small impact will cause crumbling and breaking.

Firing is where the dried parts pass through a controlled heating process, and the oxides are chemically changed to cause sintering and bonding. The fired part will be smaller than the dried part.

Assembly This process is for parts that require additional subassembly parts. In the case of a spark plug, the electrode is put into the insulator. This step does not apply to all ceramic products.

Applications

Ceramics can be used for many technological applications. One example is NASA's Space Shuttle, which uses ceramic tiles to protect it from the searing heat of reentry into Earth's atmosphere. Future supersonic space planes may likewise be fitted with such tiles. Ceramics are also used widely in electronics and optics. In addition to the applications listed here, ceramics are used as a coating in various engineering cases. For example, a ceramic bearing coating may be used over a titanium frame for an airplane. Recently, the field has come to include the studies of single crystals or glass fibers, in addition to traditional polycrystalline materials, and the applications of these have been overlapping and changing rapidly.

Aerospace

- Engines; Shielding a hot running airplane engine from damaging other components.

- Airframes; Used as a high-stress, high-temp and lightweight bearing and structural component.

- Missile nose-cones; Shielding the missile internals from heat.

- Space Shuttle tiles

- Rocket Nozzles; Withstands and focuses the exhaust of the rocket booster.

Biomedical

- Artificial bone; Dentistry applications, teeth.

- Biodegradable splints; Reinforcing bones recovering from osteoporosis

- Implant material

Electronics and electrical industry

- Capacitors

- Integrated Circuit packages

- Transducers

- Insulators

Optical/photonic

- Optical fibers; Glass fibers for super fast data transmission.

- Switches

- Laser amplifiers

- Lenses

Modern-day ceramic engineering

Modern-day ceramic engineers may find themselves in a variety of industries, including mining and mineral processing, pharmaceuticals, foods, and chemical operations.

Now a multi-billion dollar a year industry, ceramics engineering and research has established itself as an important field of science. Applications continue to expand as researchers develop new kinds of ceramics to serve different purposes. An incredible number of ceramics engineering products have made their way into modern life.

See also

Notes

- ↑ J.B. Wachtman (ed.), Ceramic Innovations in the 20th Century (Westerville, OH: American Ceramic Society, 1999, ISBN 978-1574980936).

- ↑ Robert Butler, Samantha Adams, and Meghan Humphreys, The American Ceramic Society: 100 Years (Westerville, OH: American Ceramic Society, 1998, ISBN 188890304X).

ReferencesISBN links support NWE through referral fees

- Barsoum, M. W. Fundamentals of Ceramics. McGraw-Hill Series in Materials Science and Engineering. New York: McGraw Hill, 1997. ISBN 978-0070055216

- Butler, Robert, Samantha Adams, and Meghan Humphreys. The American Ceramic Society: 100 Years. Westerville, OH: American Ceramic Society, 1998. ISBN 188890304X

- Callister, William D. Materials Science and Engineering: An Introduction, 7th ed. New York: John Wiley & Sons, 2007. ISBN 978-0471736967

- Kingery, W. D., H. Kent Bowen, and D. R. Uhlmann. Introduction to Ceramics. New York: Wiley, 1976. ISBN 0471478601

- Lampman, Steven R., Mara S. Woods, and Theodore B. Zorc. Engineered Materials Handbook, Volume 4: Ceramics and Glasses. Metals Park, OH: ASM International, 1991. ISBN 0871702827

- Rahaman, Mohamed N. Ceramic Processing and Sintering, 2nd ed. Materials Engineering, 23. New York: Dekker, 2003. ISBN 0824709888

- Richerson, David W. Modern Ceramic Engineering: Properties, Processing, and Use in Design. Engineered Materials, 1. New York: M. Dekker, 1992. ISBN 0824786343

- Smith, William Fortune. Principles of Materials Science and Engineering, 3rd ed. McGraw-Hill Series in Materials Science and Engineering. New York: McGraw-Hill, 1996. ISBN 978-0070592414

- Wachtman J.B. (ed.). Ceramic Innovations in the 20th Century. Westerville, OH: American Ceramic Society, 1999. ISBN 978-1574980936

External links

All links retrieved December 3, 2023.

| Types | Major fields of technology | Edit |

|---|---|---|

| Applied Science | Energy storage | Artificial intelligence | Ceramic engineering | Computing technology | Electronics | Energy | Engineering physics | Materials science | Materials engineering | Microtechnology | Nanotechnology | Nuclear technology | Optical engineering | |

| Athletics and Recreation | Camping equipment | Playground | Sports | Sports equipment | |

| The Arts and Language | Communication | Graphics | Music technology | Speech recognition | Visual technology | |

| Business and Information | Construction | Financial engineering | Information technology | Management information systems | Manufacturing | Machinery | Mining | Telecommunication | |

| Military | Bombs | Guns and Ammunition | Military technology and equipment | Naval engineering | |

| Domestic / Residential | Domestic appliances | Domestic technology | Educational technology | Food products and production | |

| Engineering | Agricultural engineering | Bioengineering | Biochemical engineering | Biomedical engineering | Chemical engineering | Civil engineering | Computer engineering | Electrical engineering | Environmental engineering | Industrial engineering | Mechanical engineering | Metallurgical engineering | Nuclear engineering | Petroleum engineering | Software engineering | Structural engineering | |

| Health and Safety | Biomedical engineering | Bioinformatics | Biotechnology | Cheminformatics | Fire protection technology | Health technologies | Pharmaceuticals | Safety engineering | |

| Travel and Trade | Aerospace | Aerospace engineering | Marine engineering | Motor vehicles | Space technology | Transport | |

Credits

New World Encyclopedia writers and editors rewrote and completed the Wikipedia article in accordance with New World Encyclopedia standards. This article abides by terms of the Creative Commons CC-by-sa 3.0 License (CC-by-sa), which may be used and disseminated with proper attribution. Credit is due under the terms of this license that can reference both the New World Encyclopedia contributors and the selfless volunteer contributors of the Wikimedia Foundation. To cite this article click here for a list of acceptable citing formats.The history of earlier contributions by wikipedians is accessible to researchers here:

The history of this article since it was imported to New World Encyclopedia:

Note: Some restrictions may apply to use of individual images which are separately licensed.